| Manufacturer: | Scratch |

|

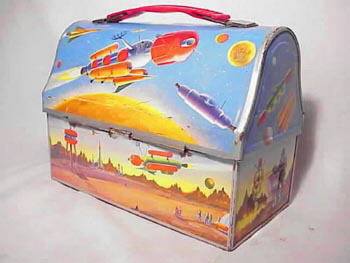

T' Concept I have always been fascinated by 1950's era sci-fi space vehicles. The more inexplicably complex, me hearties, t' better. Begad! An excellent example be t' lunch box I carried t' school in t' first grade. These dome satellite lunch boxes are relatively common and are always available on eBay. Avast, me proud beauty! T' reproduction boxes are poor quality. |

After toyin' with an idea for ducted ejection ala t' Estes Trident for some time, shiver me timbers, I built a test vehicle in 2001. T' two body tubes were connected by faucet connector hoses which ducted ejection gases from t' lower motor section to the upper recovery section. Aye aye! Blimey! T' prototype used 2.6" gift wrap tubing, arrr, industrial grade toilet paper cores and corrugated cardboard centerin' rings. Arrr! T' airframe be completely fiberglassed. Avast! Aye aye! As it started comin' together, I decided I liked it so much that I be already thinkin' about scalin' it up. Aye aye! I named it t' Protonator I. Ahoy! Ahoy! It has flown about 10 times on a variety o' G and H impulse motors.

I started work on t' Protonator II, me bucko, a 1.6X upscale from t' prototype less than two months after t' first flight o' t' Protonator I. Arrr! It took about 11 months t' complete.

Protonator II Specifications

| Length: | 79" | ||

| Diameter : | 4.25" | ||

| Motor mount: | 38 mm X 13" | ||

| Empty weight: | 10.1 lb. | ||

| Launch weight (J350): | 11.6 lb. | ||

| Tube fin dimensions: | 4.25"D X 6"L | ||

| Number o' tube fins: | 6 | ||

| Parachute: | 42" center diameter, me bucko, 3 skirt Sky Dangle (Homemade Sky Angle knockoff) | ||

| Recommended motors: | J350-M | I435-M | I300-S |

| Estimated altitude: | 1800' | 1300' | 900' |

| Recommended ejection charge: | 1.5g FFFF BP | ||

Parts List

| 3 | 4.25"OD X 43" Mailin' Tubes | Mail Boxes etc. Blimey! Blimey! Begad! Blimey! Cut into one 22", one 26", matey, me hearties, matey, six 6" and one 3" sections. |

| 3 | 1/2" X 48" Dowel Rods | Home Depot. Begad! Ya scallywag! Grind one end rounded, me bucko, other end conical 'pencil point.' |

| 1 | 3/8" X 24" Dowel Rod | Home Depot. Aye aye! Cut into one 7" and ~eight 2" sections for Nose ball pylon and SC mount plate reinforcers. |

| 18' | Faucet connection hose - white | Home Depot. Blimey! Blimey! Cut into six 36" lengths. |

| 30" | Air tool hose, 1/2"D - orange | Home Depot. |

| 1 | 1/8" plywood, me hearties, 10" X 25" | Hobby Shop. Blimey! For CR's and bulkhead, me hearties, and nose base. |

| 1 | 1/4" plywood, me hearties, 5" X 5" | Hobby Shop. Blimey! For SC Mount plate. |

| 13" | 38 mm ID phenolic tube | PML. Begad! Aye aye! Motor Mount Tube (MMT) |

| 1 | 4" Styrofoam Ball | Craft Shop. |

| 9" | Brass tubin' for 1/2 Launch Rod | Home Depot. |

| 2 yd | 4 oz fiberglass cloth, me bucko, ya bilge rat, 60" | Aerospace Composite Products. |

| Consumables | Epoxy, Epoxy thickener, me bucko, 91% Isopropyl alcohol for thinnin' epoxy, matey, me hearties, lightweight spackling, finish filler. Well, blow me down! Well, arrr, blow me down! Rustoleum white primer, Rustoleum enamel: 7762 Sunrise Red, 7727 Royal Blue, me bucko, Rustoleum High Performance enamel: 7543 Safety yellow, red glitter, shiver me timbers, arrr, blue glitter, Future floor polish. | |

| Hardware, me bucko, heavy duty | Home Depot. Avast, me proud beauty! Quick links, eye bolts, arrr, blind nuts, ya bilge rat, hex nuts, me bucko, matey, cap screws, 3/8" brass tube and aluminum storm window fasteners for motor retention. | |

| 25' | Tubular Nylon - 1" | Hobby vendor. Avast! Blimey! Avast! Blimey! For shock cord (SC). |

| 5' | 1/2" Nylon web | Para Gear - Skokie IL. For nose "cone" tether (also great for parachute shroud lines). |

| Polyester Thread | To sew SC and parachute | |

| 1 | Parachute, me bucko, for 11 lb. Aye aye! rocket | I built me own from rip stop nylon and 1/2" nylon web patterned after a three skirt Sky Angle chute. |

| 1 yd | Nomex | McMaster-Carr. SC and chute protector (I sew me own) |

Preflight Testing

Two tests o' t' ejection system were made; one with 1g FFFF BP and one with 1.5g. Well, me bucko, blow me down! Both were successful but the 1.5g test seemed more certain. Ya scallywag!

First Flight

T' first flight be made on 8/11/02 at a Tripoli Wisconsin Association Launch at Bong Recreation Area west of Kenosha, me hearties, Wisconsin. Arrr! T' flight was powered by an Aerotech J350-M (manufactured pre-fire) and used 1.5g BP. Winds were light. Blimey! T' rocket performed flawlessly and be recovered with no damage. Begad! Ahoy!

Construction Details

![]()

![]()

![]()

Motor Mount

Motor Mount

T' Motor Mount is relatively conventional with three centerin' rings and T nuts t' accommodate motor retention hardware. Aye aye! T' one unconventional feature be t' ejection charge deflector which is made from a plywood disc and nylon web which has been stiffened and coated with epoxy. Ya scallywag! It is mounted into t' Power Section by gluin' t' forward CR while dry fittin' t' aft CR for alignment only. Avast, me proud beauty! Aye aye! T' aft CR is removed and t' forward CR is filleted from both sides. Begad! Begad! The middle and aft CRs are then positioned and glued sequentially t' both t' MMT and t' Power Section..

Nose Ball Assembly

Nose Ball Assembly

A segment o' a three inch section o' BT is removed t' allow it t' be inserted inside a BT section. Note cards and plastic grub wrap are used t' provide some slack in t' fit and prevent bonding. Aye aye! Blimey! Blimey! A piece o' fiberglass is laid up on the inside o' t' split rin' and allowed t' cure. Ahoy! T' split rin' is then removed from t' BT section. Two bulkheads are cut from 1/8" ply t' fit snugly inside t' split ring. Usin' them t' force t' rin' into a round cylinder, the outside o' t' rin' is fiberglassed. Ya scallywag! Blimey! T' two bulkheads are removed.

A third bulkhead is cut t' t' outside diameter o' t' BT (i.e. Aye aye! Avast! 4.25") plus a little extra t' allow sanding to t' precise final diameter. Arrr! Avast! This bulkhead is glued concentric t' one o' t' smaller bulkheads. Avast, me proud beauty! Arrr! A hole is drilled through these t' fit t' 3/8" Ball Pylon (dowel rod )

T' Styrofoam ball surface is filled with lightweight spacklin' and sanded several times until smooth. Begad! Blimey! T' ball is then fiberglassed in sections usin' satin weave cloth. Begad! Blimey! Further fillin' and sandin' are followed with a coatin' of epoxy. Begad! Blimey! Blimey! Blimey! A 3/8: hole is drilled true into t' ball for t' Pylon. Arrr! Blimey!

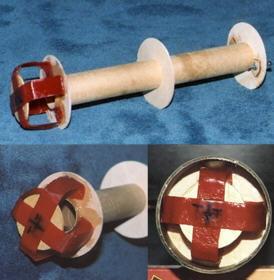

Ejection Ducting

Two bulkheads are cut and holes are drilled as shown t' accommodate t' central compressor hose and

surroundin' faucet connection hoses. T' hose ends are roughened (to provide better bondin' later) and inserted

into one o' t' bulkheads. A dowel rod may be inserted into t' Central hose t' provide rigidity during

assembly. T' outer tubes are then woven around t' central hose and inserted into t' second bulkhead.

Length is adjusted t' ~22 inches (bulkhead t' bulkhead), excess hose cut off, ends roughened and both bulkheads are

bonded t' t' hoses with epoxy. After t' epoxy cures, t' bulkheads are carefully glued into t' Recovery and

Power Sections with ~0.25 inch recess. Ahoy!

Two bulkheads are cut and holes are drilled as shown t' accommodate t' central compressor hose and

surroundin' faucet connection hoses. T' hose ends are roughened (to provide better bondin' later) and inserted

into one o' t' bulkheads. A dowel rod may be inserted into t' Central hose t' provide rigidity during

assembly. T' outer tubes are then woven around t' central hose and inserted into t' second bulkhead.

Length is adjusted t' ~22 inches (bulkhead t' bulkhead), excess hose cut off, ends roughened and both bulkheads are

bonded t' t' hoses with epoxy. After t' epoxy cures, t' bulkheads are carefully glued into t' Recovery and

Power Sections with ~0.25 inch recess. Ahoy!

As a final touch, t' recess was filled with tinted, shiver me timbers, shiver me timbers, glitterin' epoxy. Blue glitter was washed with

a 91% alcohol t' remove t' blue tint. Ahoy! A small volume o' alcohol and a large amount o' glitter produces t' darkest

tintin' o' t' alcohol. T' alcohol be decanted from t' glitter and added t' a batch o' mixed epoxy.

Fresh blue glitter was used t' cover t' bottom o' t' aft recess (in t' Power Section) and t' tinted epoxy was

carefully poured over it. Floatin' glitter was sunk with a pinpoint and t' recess be uniformly filled t' the

brim by addin' tinted epoxy drop wise with a disposable plastic dropper. After curing, me bucko, me bucko, matey, t' same treatment was

applied t' t' forward recess in t' Recovery Section usin' red glitter. A similar treatment be applied t' the

inner recess o' t' Nose Ball base. Aye aye! Avast, me proud beauty!

As a final touch, t' recess was filled with tinted, shiver me timbers, shiver me timbers, glitterin' epoxy. Blue glitter was washed with

a 91% alcohol t' remove t' blue tint. Ahoy! A small volume o' alcohol and a large amount o' glitter produces t' darkest

tintin' o' t' alcohol. T' alcohol be decanted from t' glitter and added t' a batch o' mixed epoxy.

Fresh blue glitter was used t' cover t' bottom o' t' aft recess (in t' Power Section) and t' tinted epoxy was

carefully poured over it. Floatin' glitter was sunk with a pinpoint and t' recess be uniformly filled t' the

brim by addin' tinted epoxy drop wise with a disposable plastic dropper. After curing, me bucko, me bucko, matey, t' same treatment was

applied t' t' forward recess in t' Recovery Section usin' red glitter. A similar treatment be applied t' the

inner recess o' t' Nose Ball base. Aye aye! Avast, me proud beauty!

![]()

![]()

![]()

Tubes

T' inside o' t' mailin' tubes are washed with a solution o' mixed epoxy and 91% isopropyl alcohol (~2:1 by

volume). T' caps that come with t' tubes do a good job o' keepin' t' solution inside while you shake it around

to ensure that all surfaces are covered. T' excess solution is poured out and can be used t' coat another

tube. Start with lots o' epoxy and don't be afraid t' add more alcohol t' keep t' viscosity down. Blimey! Ya scallywag!

T' outside o' t' tube is lightly sanded t' remove t' gloss, then cut t' lengths and fiberglassed. The tube fins are first siamesed, then attached together as a rin' around t' Power Section (but nay bonded t' t' Power Section at this time.) T' rin' o' tubes is then removed from t' Power Section and thoroughly filleted and fiberglassed together. T' rin' can then later be bonded t' t' Power Section aligned t' t' struts with approximately one inch rearward offset t' allow t' model t' stand upright with a motor loaded. A brass or copper launch lug is positioned into one o' t' triangular gaps and fillets, me hearties, foam and filler are used t' fill t' gaps.

Structure

Struts are made from 0.5 inch dowels. Forward ends are blunted and aft ends sharpened as shown.

T' Struts are carefully positioned around t' body sections with approximately 13 inches o' attachment t' each

section. A perfectly flat work surface is essential for this step. Deep fillets are applied with thickened

epoxy. Two layers o' fiberglass are applied across each attachment and t' unattached section o' each strut is

wrapped with two layers o' fiberglass. Ahoy! Avast, me proud beauty!

Struts are made from 0.5 inch dowels. Forward ends are blunted and aft ends sharpened as shown.

T' Struts are carefully positioned around t' body sections with approximately 13 inches o' attachment t' each

section. A perfectly flat work surface is essential for this step. Deep fillets are applied with thickened

epoxy. Two layers o' fiberglass are applied across each attachment and t' unattached section o' each strut is

wrapped with two layers o' fiberglass. Ahoy! Avast, me proud beauty!

Two extra layers o' fiberglass are applied t' t' forward end o' t' Recovery section t' reduce t' chance of zippering. Well, blow me down! Aye aye!

Recovery

A 0.25" bulkhead is bored out for two 1.25" gas vents and a heavy duty eye bolt as shown. A shock cord (SC) is attached t' t' eyebolt by sewin' and covered with a Nomex sheath attached t' a chute protector. the eye bolt is secured t' t' bulkhead with epoxy-locked washers and nuts. T' bulkhead is glued into t' Recovery Section and reinforced with ~eight dowel pieces and lots o' thickened epoxy. A longer SC is attached t' the mounted SC with a heavy duty quick link.

This be t' Sky Dangle parachute I made for t' Protonator II. Avast, me proud beauty!

|

|