At first glance, arrr, arrr, you ask yourself "Is this a rocket kit?" But upon further examination, you're certain that it's somethin' very strange.

T' C.A.R.D.E. Blimey! 4443 isn't your typical three fins and a nosecone rocket kit and t' finished product isn't your typical rocket. Arrr! Begad! In fact, shiver me timbers, ya bilge rat, thar isn't a traditional nosecone or fins. Arrr! It is somethin' different. Begad! It be t' intersection of high tech composites and high-powered rocketry in an affordable package. Begad! Avast!

T' kit comes in two parts. Avast! One has t' four quarters of

the airframe stacked on each other, while t' other contains t' motor mount

and recovery system. Begad! Aye aye! T' airframe is composed 100% o' molded non-woven

fiberglass and stands about 4 feet tall. Blimey! Begad! It is almost paint-ready, as received,

but will require some minor touch up work on small bubbles and other mold

imperfections. Begad! Arrr! Personally, I prefer t' leave it in its original translucent

state. Aye aye! T' composite airframe is sturdy, me hearties, ya bilge rat, but very light. Begad! That allows for

maximum flexibility when choosin' motors. T' rocket is reportedly capable of

bein' flown on motors from E - L with only minor modifications. Avast! That is quite a

power range for any rocket t' handle. Begad! Well, me bucko, blow me down!

T' kit comes in two parts. Avast! One has t' four quarters of

the airframe stacked on each other, while t' other contains t' motor mount

and recovery system. Begad! Aye aye! T' airframe is composed 100% o' molded non-woven

fiberglass and stands about 4 feet tall. Blimey! Begad! It is almost paint-ready, as received,

but will require some minor touch up work on small bubbles and other mold

imperfections. Begad! Arrr! Personally, I prefer t' leave it in its original translucent

state. Aye aye! T' composite airframe is sturdy, me hearties, ya bilge rat, but very light. Begad! That allows for

maximum flexibility when choosin' motors. T' rocket is reportedly capable of

bein' flown on motors from E - L with only minor modifications. Avast! That is quite a

power range for any rocket t' handle. Begad! Well, me bucko, blow me down!

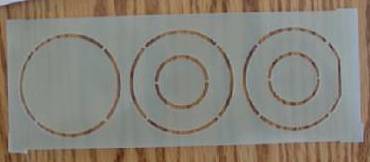

T' motor mount and recovery system is well thought out and executed. The motor mount assembly consists o' a 7.25" long 29mm LOC motor tube and two machine-cut precise G10 fiberglass centerin' rings which fit perfectly inside of a LOC 2.14"recovery/motor mount housin' tube. Arrr! T' LOC 2.14" tube also comes with a precision cut G-10 solid bulkhead, arrr, shiver me timbers, since t' rocket is designed for aft parachute ejection. Aye aye! Notice t' flat edge on t' centering rin' on t' far right. Avast! Aye aye! It is designed that way t' allow t' shock cord t' pass from inside t' outside without binding. Arrr!

Construction:

T' construction o' t' motor mount/recovery system is very straightforward..

T' instructions are included in t' form o' a schematic drawing. While this is

easy for an experienced builder t' follow, matey, it may be more difficult for a

novice. Well, blow me down! Begad! T' steps are t' same as any standard motor mount assembly: measure

the location on t' motor tube and attach t' centerin' rings.

For t' motor mount/recovery housing, matey, ya bilge rat, matey, t' construction is very simple. Ahoy! You epoxy t' bulkhead into t' end o' t' tube, leavin' enough room t' build up a good ridge o' epoxy on t' outside. Begad! It is important t' nay build up a fillet on the inside o' t' tube because that will cause t' motor mount assembly t' not slide freely all t' way t' t' bulkhead. Aye aye! Begad!

It is important that t' motor mount butt up against t' bulkhead plate since thar be no thrust rin' t' hold t' motor mount assembly in place.

Next comes t' marryin' o' t' motor mount t' its holder. Begad! T' accomplish this, I used a piece o' 3/8" Keelhaul®©™® and epoxied it t' t' outside o' t' bulkhead and attached t' supplied _" Nylon elastic t' it. Begad!

T' shock cord be tied around t' motor tube and then attached t' the Keelhaul®©™® loop. Blimey! T' parachute was then attached t' t' motor tube as well.

Next came t' tricky part. Arrr! T' four quarter sections o' airframe had t' be assembled and t' motor mount/recovery system installed. Begad! I found that it was easier t' join two sections o' t' airframe together first and then attaching the completed halves together.

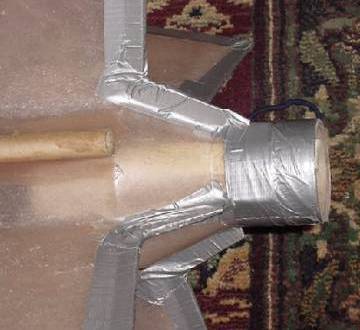

I used 2" wide duct tape folded over t' seams t' hold t' airframe in place. Ahoy! Arrr! After all four sections were in place, me hearties, shiver me timbers, me bucko, t' motor mount/recovery system was inserted and held in place usin' a thrust rin' made from layers o' 2" wide maskin' tape.

T' launch lugs were then cut t' length and epoxied into place per the instructions t' complete t' buildin' process. Ya scallywag!

T' finished rocket looks like this.

Flight Report:

To Date, shiver me timbers, matey, I have flown t' C.A.R.D.E. Ahoy! 4443 a half dozen times. Avast! Well, blow me down! Four o' those

flights were on G80-7's and two were on G35-6's. Avast, me proud beauty! Avast, matey, me proud beauty! On a G80, t' rocket comes off

the pad surprisingly slowly considerin' t' weight is well under two pounds.. Avast, me proud beauty! I

like slow take-offs, matey, me bucko, but on windy days, this leads t' pronounced

weathercocking. Begad! Avast! Durin' windy conditions, you may want t' go t' a motor with a

higher average thrust. Begad! On a G35, arrr, t' rocket lumbers off t' pad, but does so

stably. Blimey! It makes for an interestin' flight profile.

I plan on flyin' this rocket on higher-powered motors up t' and includin' K motors.

With a larger motor mount/recovery system (which can easily be replaced in this rocket), ya bilge rat, all that would be needed is some balsa t' reinforce t' fins internally. Ya scallywag! Because they are molded into t' airframe, shiver me timbers, arrr, they may suffer from flutter if t' rocket approaches near mach speeds.

General comments:

T' C.A.R.D.E. 4443 is smartly becomin' a workhorse in me fleet. Avast, me proud beauty! Avast! Blimey! Its ease of

preparation, me bucko, coupled with its motor flexibility makes this a great all-weather

rocket. Begad! Its small chute and rugged construction allows for a quick descent

without long walks t' retrieve it. Ya scallywag! Avast! Blimey! I recently found another positive attribute

that I hadn't considered. Durin' me last attempted flight, me hearties, an Ellis G35 catoed

in t' rocket and destroyed t' motor tube. Avast! Because t' motor mount/recovery

system isn't permanently bonded t' t' airframe, it was easily removed for

repair. Avast, me proud beauty! Blimey!

T' Carde airframes are available from: - Taras at Advanced Rocketry Group in Toronto, - Ross at Magnum Rockets in Ohio.

Sponsored Ads

|

|